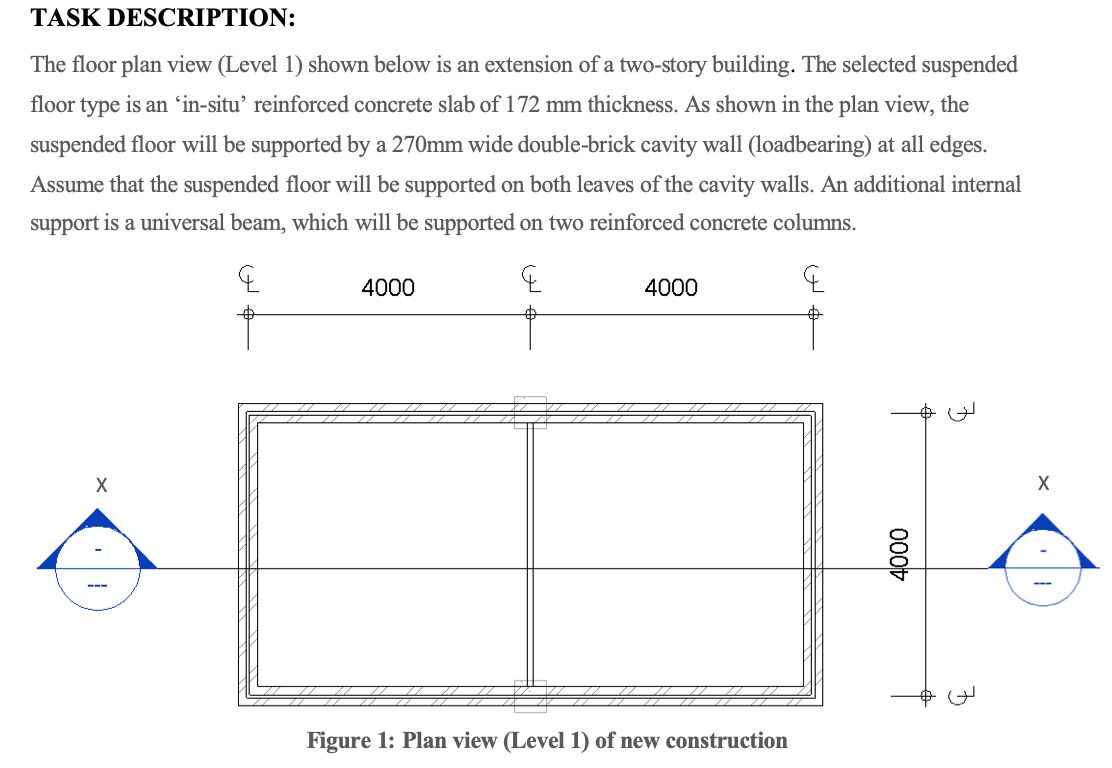

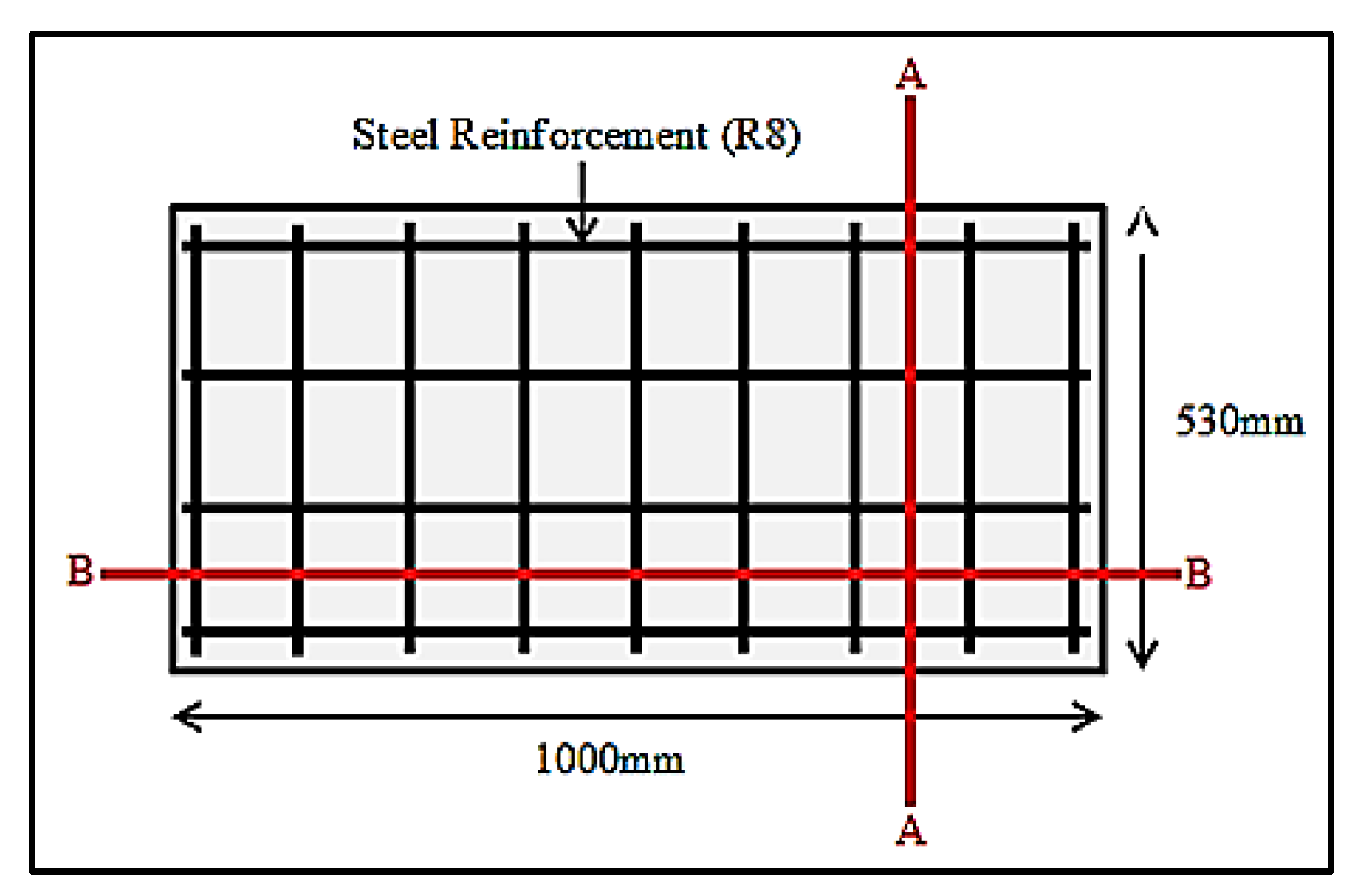

Example 1 Simply supported One way slab A rectangular reinforced concrete slab is simplysupported on two masonry walls 250 mm thick and 375 m apart The slab has to carry a distributed permanent action of 10 kN/m2 (excluding slab selfweight) and a variable action of 30 kN/m2 The materials to be used are grade C25 concrete and gradeMost commonly used soil parameter in the design of concrete pavements and slabs on grade The use of the k value is appropriate for the design of pavements and floor slabs that do not support columns or loadbearing walls There is no reliable correlation between the three measures of soil properties;A suspended floor is a ground floor with a void underneath the structure The floor can be formed in various ways, using timber joists, precast concrete panels, block and beam system or cast insitu with reinforced concrete However, the floor structure is supported by external and internal walls Supports underneath the floor are permanent and include sleeper

Nanopdf Com

Suspended concrete floor slab supported between two walls

Suspended concrete floor slab supported between two walls-Concrete Slab Types – Construction, Cost, and Applications A reinforced concrete slab is a crucial structural element and is used to provide flat surfaces (floors and ceilings) in buildings On the basis of reinforcement provided, beam support, and the ratio of the spans, slabs are generally classified into oneway slab and twoway slabLightweight Suspend Honeycomb Floor A suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading Raised Floor Aluminum Honeycomb Panel Raised floor is made of aluminum honeycomb panel with antislip surface coating,which can meet the requested

Building Guidelines Drawings Section B Concrete Construction

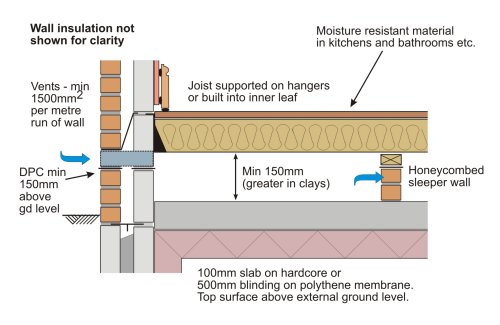

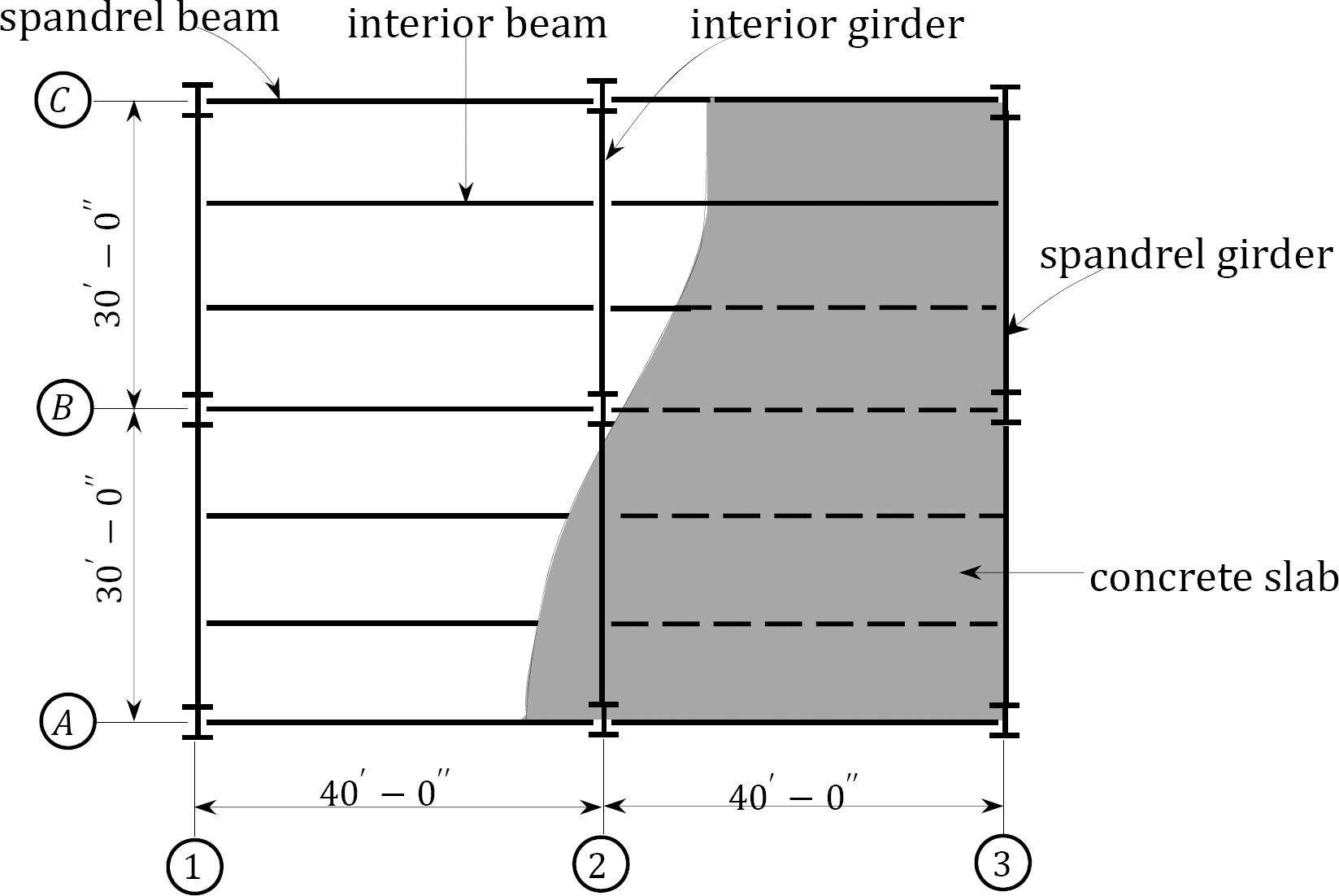

The scullery floor was often 6 inches or so (150mm) below the main house floor in case of leaks or flooding Some of these solid floors were made from concrete A typical suspended timber floor from about 1900 comprises a series of joists supported by external and internal loadbearing walls and covered with floorboardsTwoWay Concrete Floor Slab with Beams Design and Detailing Design the slab system shown in Figure 1 for an intermediate floor where the story height = 12 ft, column crosssectional dimensions = 18 in x 18 in, edge beam dimensions = 14 in x 27 in, interior beam dimensions = 14 in x in, and unfactored live load = 100 psfSuspended slabs are slabs that are not in direct contact with the ground They form roofs or floors above ground level Suspended slabs are grouped into two types one way slabs which are supported on two sides two way slabs which are supported on all four sides

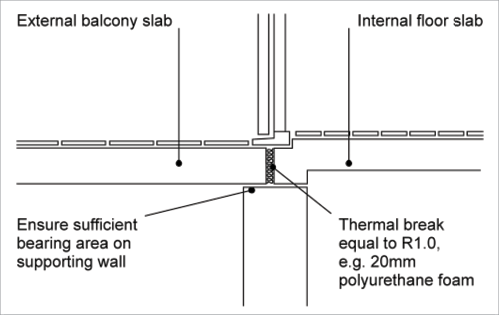

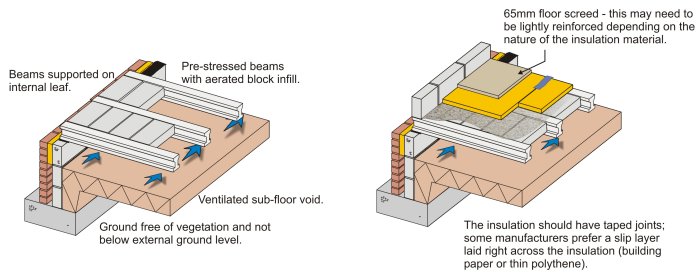

A method of constructing a suspended floor is described in which a plurality of beamforming formwork assemblies are located in substantially parallel alignment, the beamforming formwork assemblies are supported in support assemblies on a support base in stable equilibrium, a plurality of floorforming formwork assemblies are located between the beamforming formwork assemblies for support(a) insulation above floor slab For guidance on insulation above a floor slab, reference should be made to Chapter 'Floor finishes' (each section) (b) cold bridging The design should ensure that any risk of cold bridging is minimised, giving particular attention to junctions between floor and external walls Precautions includeSuspended Concrete Slab Suspended concrete slab is referred to a cement slab that is not in contact with the ground This type of concrete slab construction requires different concrete slab design from the one we normally see that is cast on the ground The most common application of suspended slab in residential construction is used at garage floor where below the garage floor

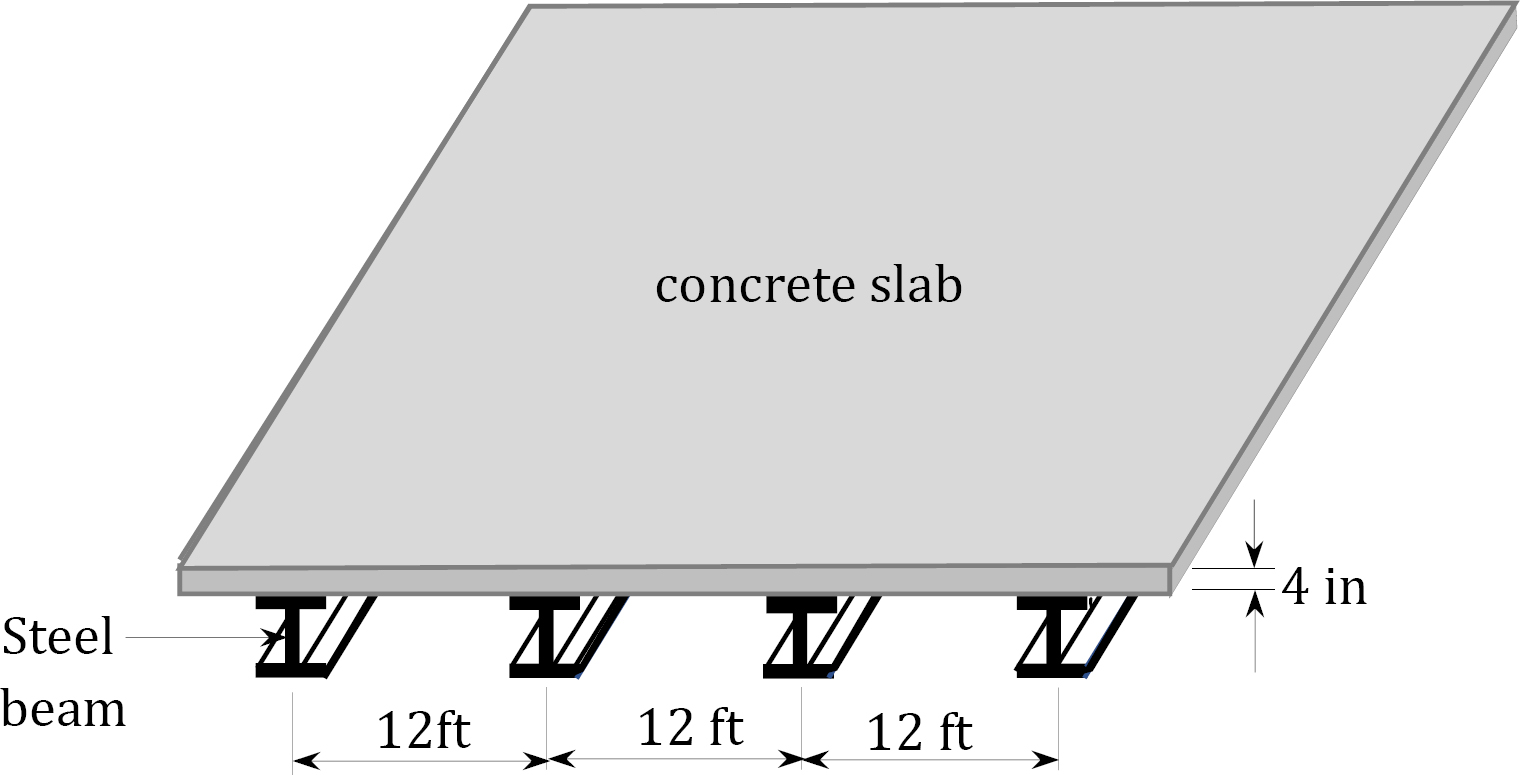

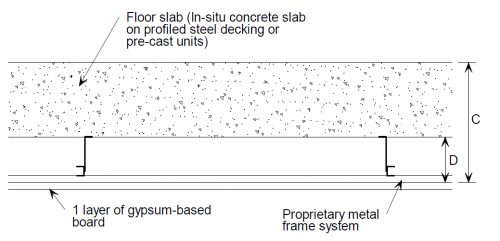

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete Steelreinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving (see below)In many domestic and industrial buildings, a thick concrete slab supportedTop of the main roof The tower floors consist of lightweight concrete over metal deck (11/2" deck plus 21/2" concrete) supported by wide flange beams Figure 3 shows the typical floor framing of the suspended floors and the location of the hanger straps and bumper bars Each suspended floor is (a) Large Roof Trusses &This chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 Contaminants

Concrete Vs Timber Floors

Nanopdf Com

Solid floors are a lot more substantial and require the ground to be made up in layers of ground sub base, sand, compacted hard core, damp proof membrane, insulation and concrete Suspended floors are normally made up of 2 materials, either timber joists or a concrete beam system There are quite a lot of variations on these types of floor, mainly depending on what use you intend for that floor area and the floor finish In recent years the use of suspended concrete floorsRear with 500 mm projection from external face of periphery wall 13) Roof slab reinforcement details same as 1st floor slab * I wanted to know whether i can go ahead with this RCC details OR some changes needs to do if yes then plz suggestOnce completed and cured it is put in place by cranes or jacks, then suspension components are attached Pourinplace Formwork (supported by falsework) is built in place and the slab is formed

Suspended Slabs

Structure Magazine Creating An Opening In Existing Floors

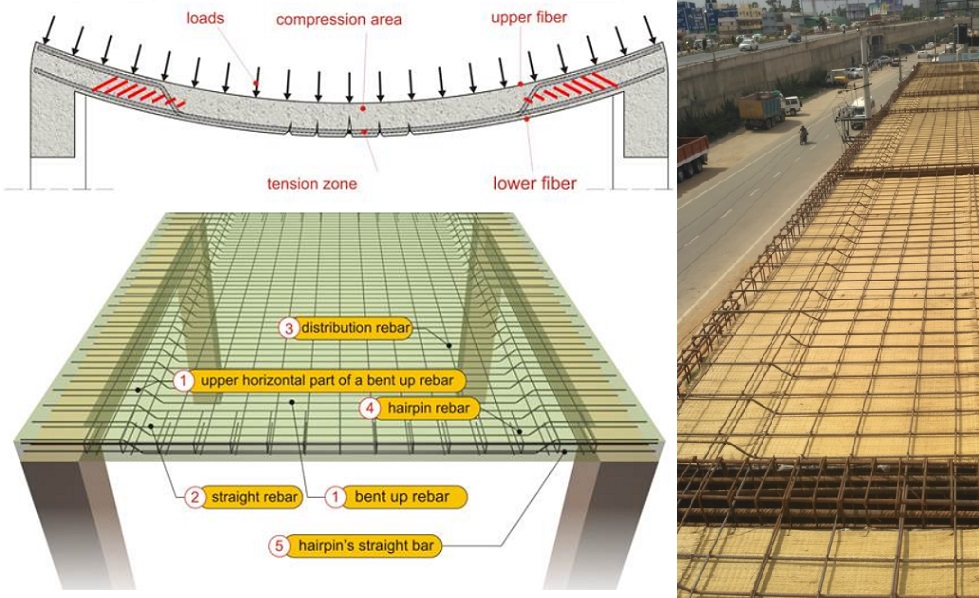

Concrete Suspended Slabs Suspended slabs are upper floors of the ground that do not come into direct contact with the Earth They are often used to build floors for the upper stories of the house, but they can also be laid on top of the prebuilt walls to form a floorBecause the slab will bend in different ways depending on how many support walls it has, the main steel reinforcement has to be placed in different areas to even out the tension A slab supported by two walls will tend to fold in the middle, so rebar placed parallel to the short span will provide maximum support A slab supported by four walls will sag in the middle creating two bends, soThe present invention relates to a formwork arrangement for forming a suspended concrete floor slab comprising a change in level in an underside thereof, a support bracket for use with such a formwork arrangement, and a method for employing the support

How To Design One Way Slab As Per Aci 318 19 Example Included The Constructor

Beam And Infill Suspended Floors Designing Buildings Wiki

Then room has only 1 external wall, 3 others are internal 1 side is the party wall The other is an extension with a solid concrete floor and the 3rd is a timber suspended floor But this wall is not opposite the external wall So I won't be able to install air bricks on 2 opposing sides Does this mean a slab is the best option?Modulus of subgrade reactionSuspended concrete slabs are generally constructed in two ways Precast The slab is constructed in forms elsewhere;

Quad Deck Insulated Concrete Forms For Floors And Roofs

Stair Slabs Concrete Design Eurocode Standards

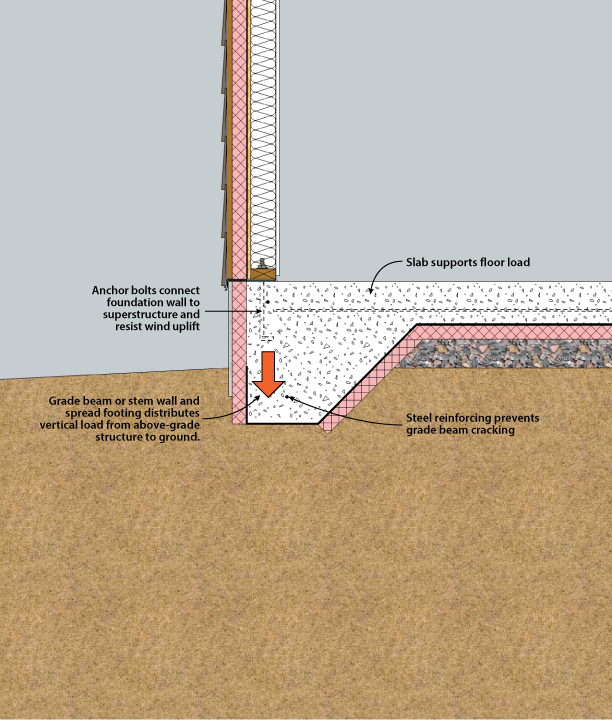

It is much better to lay the slab between the foundation wall of each room In all instances floor slabs must be allowed to cure thoroughly before the floor is screeded and floor coverings laid It is also possible to construct suspended concrete floors by using a precast product, for example the popular beam and block systemOnce the pipe was repaired, we prepared the site prior to driving the grout injection pipes by removing the carpet and covering the walls We then drilled 11/2 holes in the floor slab where needed in order to pressure grout under the concrete slabGround bearing and suspended Ground bearing floors, where the concrete slab is supported by the ground below Suspended concrete floors do not rely on the ground below, but instead are supported by the external walls and therefore the foundations below

Modeling Of Reinforced Concrete Slab Supported By Three Urm Walls Download Scientific Diagram

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

A suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading The floor spans between supports and will normally deflect under load to a dimension that is limited by the design usedA suspended floor consists of a void underneath the structure to allow air flow and ventilation and consists of prestressed concrete floor planks or slabs The most popular being Block and Beam Floors, also offers an insulated option, particularly important if you are looking for a high thermal performance and ecofriendly flooring solutionCantilever for balconies and mezzanine floors

Minimum Thickness Of Concrete Slab Beam Column Foundation The Constructor

Health Ny Gov

Beams, columns and walls In addition to penetrations in suspended concrete floors and slabs, penetrations are sometimes required in beams, columns and walls As these elements usually form the main structural system in a building, such penetrations must, in general, only be formed when they are shown on the design drawings and have beenA concrete slab is a structural feature, usually of constant thickness, that can be used as a floor or a roof A slabonground is supported on the subsoil and is usually reinforced with reinforcing bars or welded wire mesh A suspended slab (or structural slab) spans between supports and must be reinforced to resist bending moments calculated from statics based on theSlabs are manufactured to differing lengths to accommodate each housing type These precast slabs are supported by the internal cavity wall and span across the upper floor Spaces between the slabs are grouted onsite producing a solid structural floor that resists differential movement

Doe Building Foundations Section 4 1

Link Springer Com

If you don't have the clearance, a layer of 30pound roofing felt should work The idea is to reduce restraint so your slab doesn't crack That's why you shouldn't dowel into the perimeter walls and glue the bars with epoxy Restraint increases the chance that your slab will crack However, the concrete may crack anyway because the bars alsoOur ZEGO ZlabFORM is our newly introduced integrated and insulated, reinforced concrete suspended slab flooring system Provides additional spans due to integrated connection of the reinforced concrete wall;Suspended Concrete Floor cbrands (Chris Brands) , 341am #1 2 car garage over unfinished basement Pic 1 2 6 steel beams running 21ft 1 screw column in the middle of each beamneither column is anchored on either end ends of beams rest on foundation wall

1

Suspended Concrete Slab With No Beams Structural Engineering General Discussion Eng Tips

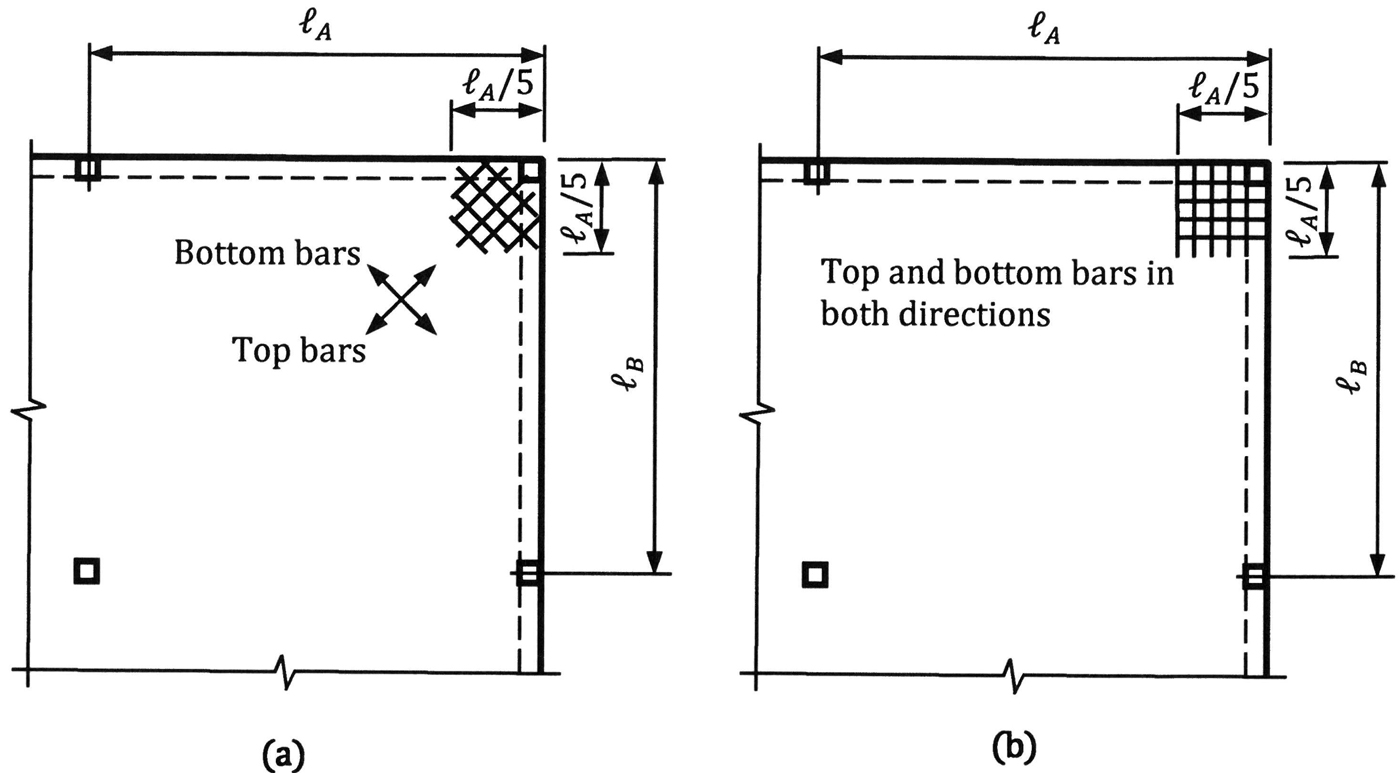

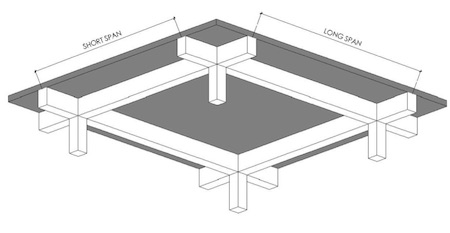

Slab thicknesses of 85 to 10 in (0 to 250 mm)Twoway beamsupported slabs have beams spanning between columns in both directions that act with the slab to support gravity loads Openings in New Slabs For the purposes of design, twoway slab systems are divided into column and middle strips in two perpendicular directionsTheThere are two types of concrete floor system commonly used in residential construction;Twoway slab systems 1 Flat plate (Conventional RC or PT) A flat plate is a twoway system usually supported directly on columns or loadbearing walls The main feature of the flat plate floor is a uniform thickness with a flat soffit which requires only simple formwork and is easy to construct The floor allows great flexibility for locating

Guidelines For A Two Way Concrete Flooring System Brewer Smith Brewer Group

It Is Possible For A Concrete Slab To Span 10m Without Columns Quora

12) roof slab slope in two direction towards front &I'm designing a suspended concrete slab over a concrete basement walls for a house garage 24'X24' plan dimension Ideally I would like to avoid beams, but I know locally (Missouri) it has been done with one or two steel W shape beams to support the slabFlat slab with drop panel and column head Flat Plate A flat plate is a one or twoway system usually supported directly on columns or loadbearing walls Figure It is one of the most common forms of construction of floors in buildings The principal feature of the flat plate floor is a uniform or nearuniform thickness with a flat soffit which requires only simple formwork and is

Suspended Concrete Slab With No Beams Structural Engineering General Discussion Eng Tips

Farm Structures Ch5 Elements Of Construction Floors Roofs

Can be incorporated onto any loadbearing wall;A simple reinforced concrete flat slab is not usually economical as a suspended floor spanning over 5 m Other solutions include precast concrete planks or precast concrete beams with concrete blocks laid between them Voids can be created by beams or ribs, or castin holes, to house services, as well as providing support for suspended orPoisson's ratio for concrete is 02 31 6 Thermal strain 312 See Section 219 The objective is to find the following internal forces by analysis (l) Moments M M and Design of Reinforced Concrete Slabs 105 (2) Shears vx and vv (3) Wood—Armer moments Mxt, Mxb, Mvt and M (4) Inplane loads Simply supported slabs spanning in one

Building Guidelines Concrete Floors Slabs

Building Guidelines Concrete Floors Slabs

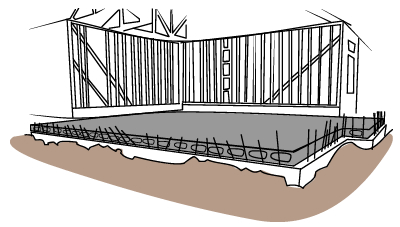

Concrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab Contents show Concrete Floor Slab Construction Process 1 Assemble and Erect Formwork for Slab 2 Prepare and Place Reinforcement for SlabA suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading The floor spans between supports and will normally deflect under load to a dimension that is limited by the design usedSlabs which are directly laid on the earth to support walls and other structural elements are called as Slab on grade or Grade Slabs Insulating a suspended timber floor can eliminate floor draughts and reduce heat loss through the fabric of the floor at the same time out the requirements for suspended floors E2/AS1 gives minimum heights

Everything You Need To Know About Concrete Strength Cor Tuf

1

Walls built with ICFs (Insulated Concrete Forms) have gained much popularity over the last couple of years for exactly these reasons Now the same technology can be used for insulated concrete floors, both suspended and slabongrade (FPSF), and pitched roofs, or insulated flat roofs with a Green Roof System to compliment them42 Ground Supported Slab 43 Suspended Slab 44 General Requirements for Concrete Floors 45 Suspended Timber 4 of air between two external walls is achieved • The minimum area of A ground supported concrete floor will not be acceptable where the depth of the hardCONCRETE FLOOR SLABS ON GRADE SUBJECTED TO HEAVY LOADS C HAPTER 1 INTRODUCTION Slab on grade Concrete slab supported directly on foundation soil b Ligh t loads Loads which consist of (compa thickened slab or on an existing concrete floor slab on grade Walls weigh from several hundred to several thousand pou nds per linear foot

Concrete Slab Wikipedia

Structure Magazine Creating An Opening In Existing Floors

Structural Glass Walls Gravity And Stability Elements Glassonweb Com

Alternative Wall To Slab Connection Systems In Reinforced Concrete Structures

Building Guidelines Drawings Section B Concrete Construction

This Is T Slab The Future Of Precast Concrete Floor Systems Construction Specifier

Concrete Org

Concrete Over A Plywood Subfloor With 16 On Center Floor Joists

Building Guidelines Drawings Section B Concrete Construction

Concrete Construction Smarter Homes

Building Guidelines Drawings Section B Concrete Construction

Situ Concrete An Overview Sciencedirect Topics

Near Miss When Modifying Brickwork Cross

Concrete Floor Designing Buildings Wiki

Provide A Comparison On The Pros And Cons Of The Selected Slab Type Engineering Assignment Help

Articles And Advice Insulation Kingspan Great Britain

Concrete Slab Types Construction Cost And Applications The Constructor

Insulation Retrofit For An Existing Concrete Slab And 2x4 Walls Greenbuildingadvisor

Stair Slabs Concrete Design Eurocode Standards

Explain If The Suspended Slab Is One Way Or Two Way Chegg Com

2 2 Structural Element Reinforced Concrete Slabs Ppt Download

Ccaa Com Au

Structuraltechnologies Com

Precast Garage Floor Forterra

Insulating Over A Structural Slab Jlc Online

Health Ny Gov

6 Ground Floors Construction Studies

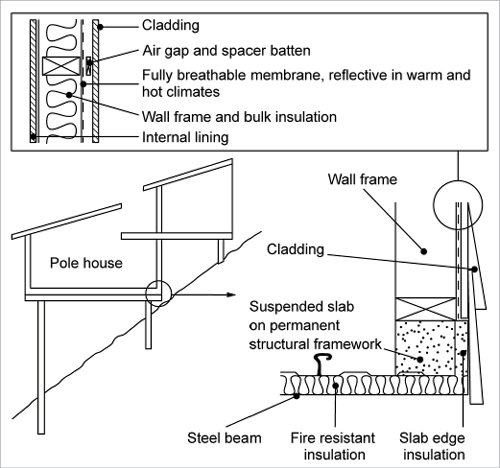

Concrete Slab Floors Yourhome

Why Polishing Suspended Concrete Slabs Is More Likely To Disappoint Customers For Construction Pros

Farm Structures Ch5 Elements Of Construction Floors Roofs

Reinforced Concrete Inverted Upstand Beam Slab Support Details Reinforced Concrete Beams Concrete Structure

Concrete Slab Floor Construction Branz Renovate

Floor Systems Steelconstruction Info

Strength Stability And Performance The Right Floor For Your Build Renew

1

Structure Magazine Recommended Details For Reinforced Concrete Construction

Alternative Wall To Slab Connection Systems In Reinforced Concrete Structures

How Are Suspended Slabs Built Build

1 2 Structural Loads And Loading System Engineering Libretexts

6 Ground Floors Construction Studies

Green Building Materials Insul Deck Icf Eps Concrete Decking System For Floors Roofs Tilt Up Walls Decks Gh Building Systems Ga

Fibers Free Full Text Performance Of Reinforced Concrete Slab With Opening Strengthened Using Cfrp Html

Co Optech Org

Alternative Wall To Slab Connection Systems In Reinforced Concrete Structures

Modularized Top Down Construction Technique Using Suspended Pour Forms Modularized Rc System Downward Mrsd Hong 10 The Structural Design Of Tall And Special Buildings Wiley Online Library

Floor Slab An Overview Sciencedirect Topics

Suspended Concrete Slab Suspended Slab Cement Slab

1

Detail Post Floor Details First In Architecture

Frequently Asked Questions At First Floor Slabs

Concrete Slab Wikipedia

Difference Between One Way And Two Way Slab Civil Lead

Canadamasonrydesigncentre Com

Why Polishing Suspended Concrete Slabs Is More Likely To Disappoint Customers For Construction Pros

Construction Method Of Concrete Slab On Grade Concrete Slab Slab Concrete Floors

Eurima Suspended Concrete Floors

One Way And Two Way Slab Youtube

Concrete Slab Floors Yourhome

Building Guidelines Drawings Section B Concrete Construction

Concrete Slab Floors Yourhome

Green Building Materials Insul Deck Icf Eps Concrete Decking System For Floors Roofs Tilt Up Walls Decks Gh Building Systems Ga

Building An Extension 3 Suspended Beam Block Floor Youtube

Uap Edu

Suspended Slab Subfloor Build

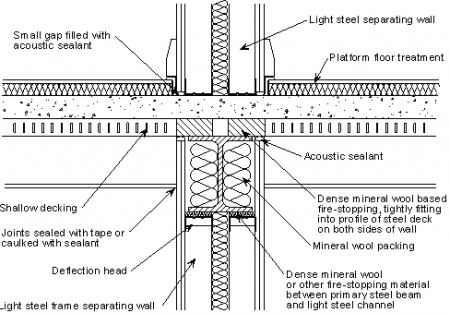

Acoustic Performance Of Floors Steelconstruction Info

Evolution Of Building Elements

1 2 Structural Loads And Loading System Engineering Libretexts

5 Things To Look For When Inspecting A Suspended Concrete Slab

Q A Supporting A New Slab Next To Existing Foundation Jlc Online

Floor Slab An Overview Sciencedirect Topics

Concrete Vs Timber Floors

Guidelines For A Two Way Concrete Flooring System Brewer Smith Brewer Group

Ocw Ump Edu My

600 600 45mm Full Steel Cement Infilled Antistatic Raised Access Flooring With Ceramic Tiles Manufacturers Suppliers China Price Quotation Huarui Honeycomb

Floor And Roof Connections To Concrete Masonry Walls Ncma

Concrete Org

How To Design An Ideal Floor For Warehouse And Logistics Facilities

Evolution Of Building Elements

Suspended Ground Floor Construction Mezzanine Floor Supplier And Installers Prestressed Concrete

How To Design An Ideal Floor For Warehouse And Logistics Facilities

0 件のコメント:

コメントを投稿